Cranes and heavy machinery are powerful—and dangerous. Our AI-powered Environmental Health & Safety (EHS) system detects people and obstacles in real-time, automatically halts equipment and triggers operator alerts before accidents happen.

When installed on a mobile or fixed crane (Crawler, Floating, Gantry, Tower), or heavy construction equipment (excavators, back-hoe, trenchers, hoisting equipment), our system adds an intelligent safety layer that reacts faster than any human can.

Even with the best training and procedures, humans have blind spots. Our AI system doesn’t blink—it watches the scene continuously, processes information instantly, and responds automatically.

Let us show you how we can enhance your safety protocols with minimal downtime or disruption.

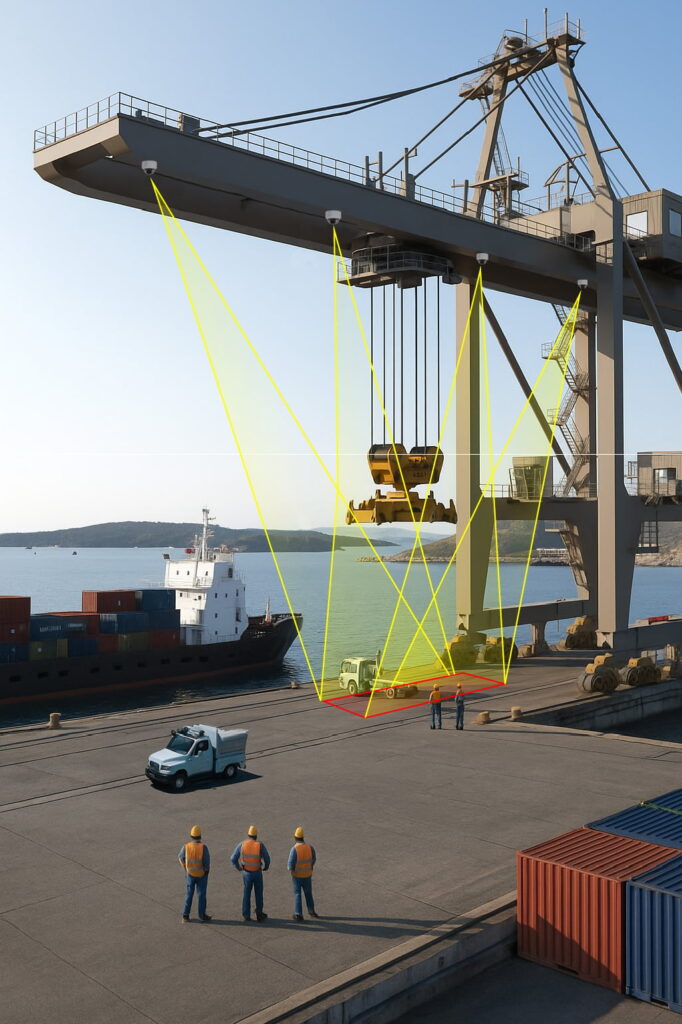

For big fixed cranes like Overhead (Gantry, Bridge, Monorail Cranes), Bulkhandlers, Hammerhead, Stackers, Telescopic or Tower cranes, strategically mounted cameras can detect unauthorized entry into any zone configured during system set-up. Our SOHO product can monitor up to 4 zones

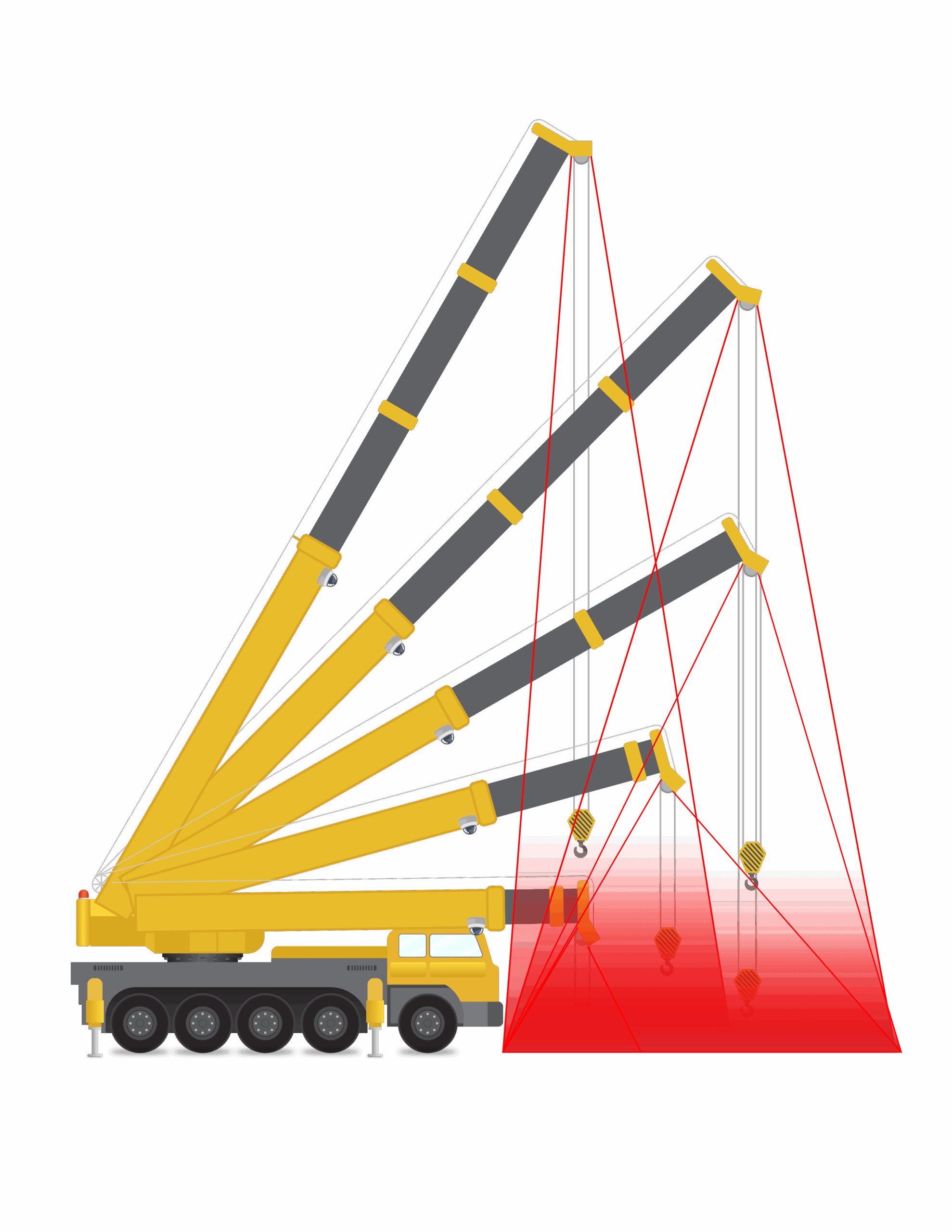

No matter what size mobile crane you have, seeing the danger zone under the hook block is imperative to keeping riggers safe. Mobile cranes present a challenge to visual alert systems since the danger zone moves with the hook block and mounting a good quality camera on a hook block is very challenging due to vibration and power issues. Our system takes advantage of the main boom collars for cameras. The camera focal area can be optimized to ensure the greatest danger zone area even as the boom telescoping sections move.

The SOHO Product comes in a wall mountable enclosure or a rack mountable enclosure.

Note: Detection logic is proprietary. System tuning and custom model training available.